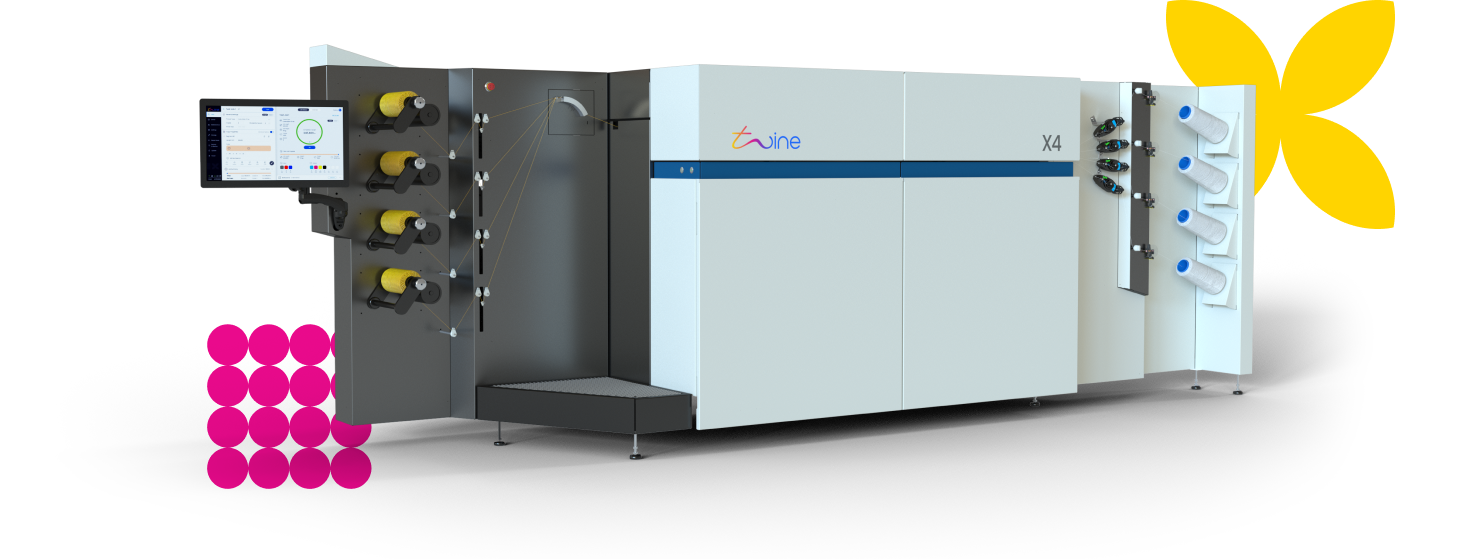

Transform your production with TwineX4

Waterless digital thread and yarn dyeing

What We Do

We are changing the game of the traditional, resource-intensive, thousand-year-old dyeing process.

Twine’s technology & solution presents a waterless, sustainable thread-dyeing system, which can reduce time to market, streamline your inventory management while enabling an unlimited color palette.

You’re in good company

Our technology

We do to yarn dyeing what digital printing did to offset — new, original, disruptive. Our Twine technology presents a game-changer as it enables dyeing at the level of the individual thread.

Be fast

Go from design to sample creation in hours. Make quick designs for on-demand fashion.

Be efficient

Dye the exact length you need. No MOQs. No shipping. No extra storage space required.

Be creative

Millions of colors are at your fingertips. Stay ahead of the latest seasonal colors and fashion trends.

Be sustainable

Applications

From apparel to knitting and sewing, our digital dyeing technology easily adapts to the quantity you need – from product development to production.

To lead the digital transformation in the thread and textile industries for better performance and greater sustainability

Who we areInterested in getting your own TS-1800?

We have a growing network of distributors bringing our digital thread and yarn dyeing machine around the world! Find out where to get the TS-1800 near you

Register to our Newsletter

Hatnufa 7 | Kiryat Arie, Petach Tiqva | 4951025 – Israel P.O Box: 3391

+972-3-5589505